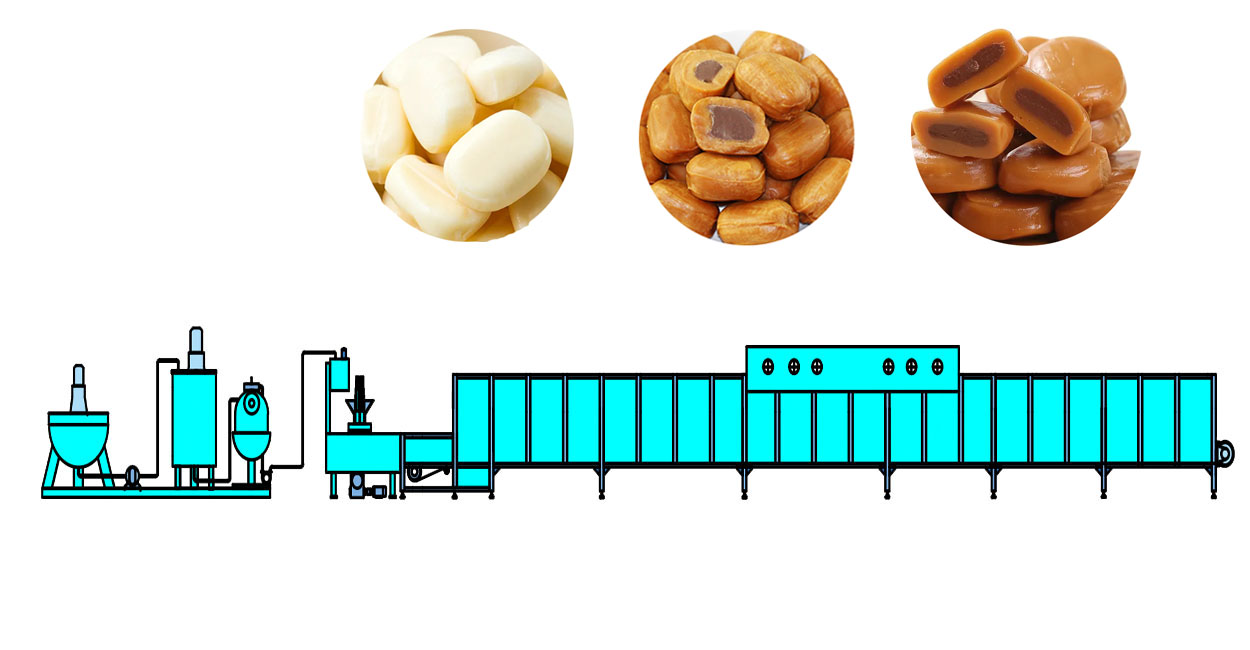

Toffee Candy Depositing Production Line

A toffee candy depositing production line is a specialized assembly of equipment used for the automated manufacturing of toffee candies. This production line is designed to efficiently produce a large volume of toffee candies with consistent quality and shape. It typically consists of several key co......

Send Inquiry

Product Description

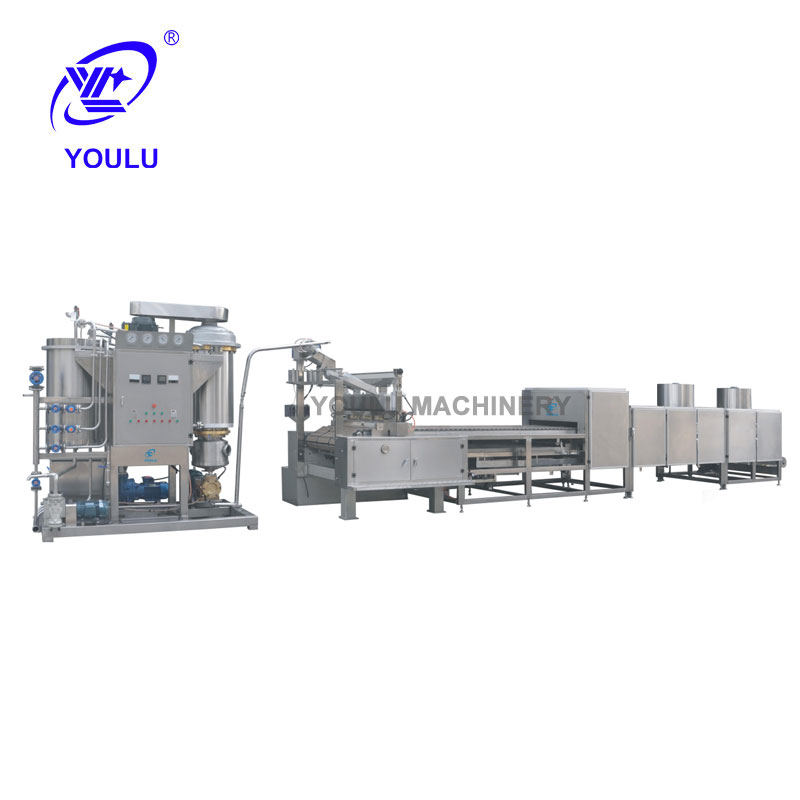

A toffee candy depositing production line is a specialized assembly of equipment used for the automated manufacturing of toffee candies. This production line is designed to efficiently produce a large volume of toffee candies with consistent quality and shape. It typically consists of several key components:

1. Mixing and Cooking System: The production line begins with a mixing and cooking system. It combines ingredients like sugar, glucose syrup, milk solids, fats, flavorings, and other additives. The mixture is heated and cooked to a specific temperature to achieve the desired consistency and texture of the toffee.

2. Depositing Machine: The heart of the production line is the toffee depositing machine. This machine deposits the cooked toffee mixture into precise molds or trays to form individual toffee candies. The depositing machine can be configured to create different shapes, sizes, and patterns of toffees based on the specific requirements.

3. Cooling Tunnel: Once the toffee candies are deposited, they need to cool and solidify. The production line typically includes a cooling tunnel, where the trays or molds containing the deposited toffees are transported through a temperature-controlled environment. This ensures proper cooling and solidification of the candies.

4. Demolding System: After the toffee candies have cooled and solidified, a demolding system is used to remove them from the molds or trays. This system may include mechanical or pneumatic mechanisms to gently release the candies without damaging their shape.

5. Wrapping and Packaging: Once the toffee candies are demolded, they can be wrapped individually or packaged in bulk. The production line may have an integrated wrapping or packaging system that automatically wraps each toffee candy or packages them in bags, boxes, or other containers suitable for distribution.

6. Controls and Automation: Modern toffee candy depositing production lines often feature advanced controls and automation systems. These systems allow operators to set parameters such as cooking temperature, depositing speed, cooling time, and wrapping options. Automation helps improve production efficiency, consistency, and reduce human error.

It's important to note that the specific features and configurations of a toffee candy depositing production line can vary depending on the manufacturer and model. Different machines may offer additional functionalities or variations in the manufacturing process.

If you're interested in purchasing or learning more about toffee candy depositing production lines, I recommend contacting confectionery equipment manufacturers or suppliers. They can provide detailed specifications, pricing information, and further assistance based on your specific needs and production requirements.