Applications of Hybrid Stepper Motors

2024-06-03

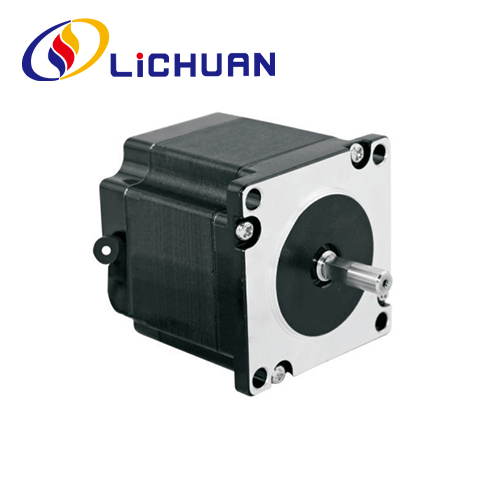

A hybrid stepper motor is a type of stepper motor that combines features of both permanent magnet (PM) stepper motors and variable reluctance (VR) stepper motors. It is sometimes referred to as a hybrid synchronous stepper motor. Hybrid stepper motors offer a balance between the advantages of PM and VR stepper motors, resulting in improved performance characteristics, such as higher torque, better precision, and smoother operation. Here's an overview of the key features and workings of hybrid stepper motors:

Features of Hybrid Stepper Motors:

1. Hybrid Design: Hybrid stepper motors feature a unique design that combines the rotor structure of a PM stepper motor with the stator structure of a VR stepper motor. This hybrid design allows for enhanced performance and efficiency compared to traditional stepper motor designs.

2. Variable Reluctance Stator: The stator of a hybrid stepper motor typically consists of multiple teeth or poles arranged in a specific pattern to create variable reluctance paths. This design helps improve the motor's torque characteristics and efficiency by maximizing the magnetic flux linkage between the rotor and stator.

3. Permanent Magnet Rotor: The rotor of a hybrid stepper motor contains permanent magnets arranged in a specific configuration to create a magnetic field. This magnetic field interacts with the variable reluctance stator to produce rotational motion when electrical currents are applied to the motor windings.

4. High Torque Density: Hybrid stepper motors are known for their high torque density, meaning they can deliver high levels of torque relative to their size and weight. This makes them suitable for applications requiring high torque output in compact spaces.

5. Precise Positioning: Hybrid stepper motors offer precise positioning capabilities, making them well-suited for applications that require accurate control of rotational motion, such as robotics, CNC machines, 3D printers, and automated equipment.

6. Smooth Operation: Due to their hybrid design and advanced construction techniques, hybrid stepper motors often exhibit smoother operation and reduced vibration compared to traditional stepper motors. This helps improve overall system performance and reliability.

7. Microstepping Capability: Many hybrid stepper motors support microstepping, a technique that allows for finer resolution and smoother motion control by subdividing each step into smaller increments. Microstepping helps reduce vibration, improve accuracy, and minimize audible noise during operation.

Applications of Hybrid Stepper Motors:

- CNC machines (Computer Numerical Control)

- 3D printers

- Robotics

- Automated manufacturing equipment

- Medical devices

- Laboratory instrumentation

- Textile machinery

- Packaging machinery

- Automotive systems

- Aerospace systems

Overall, hybrid stepper motors offer a versatile and efficient solution for a wide range of motion control applications, combining the benefits of permanent magnet and variable reluctance stepper motor technologies to deliver high performance, precision, and reliability.