Aspects of steel wire ropes

2023-11-15

A steel wire rope, commonly known as wire cable, is a type of cable made up of steel wires twisted together to form strands. These strands are then twisted together to create a robust and flexible assembly. Steel wire ropes are widely used for various applications where strength, durability, and flexibility are crucial. Here are key features and aspects of steel wire ropes:

1. Composition:

- Steel wire ropes are typically composed of individual steel wires that are helically wound or twisted into strands. The strands are then helically wound around a central core to form the final wire rope.

2. Strands:

- Strands are individual bundles of steel wires twisted together. The number of wires in a strand and the arrangement of these wires (such as regular or compacted) can vary, affecting the properties of the wire rope.

3. Core:

- The core of a steel wire rope provides support to the strands and helps maintain the rope's shape and strength. Cores can be classified into fiber cores (made of natural or synthetic fibers) or steel cores (made of additional steel wires).

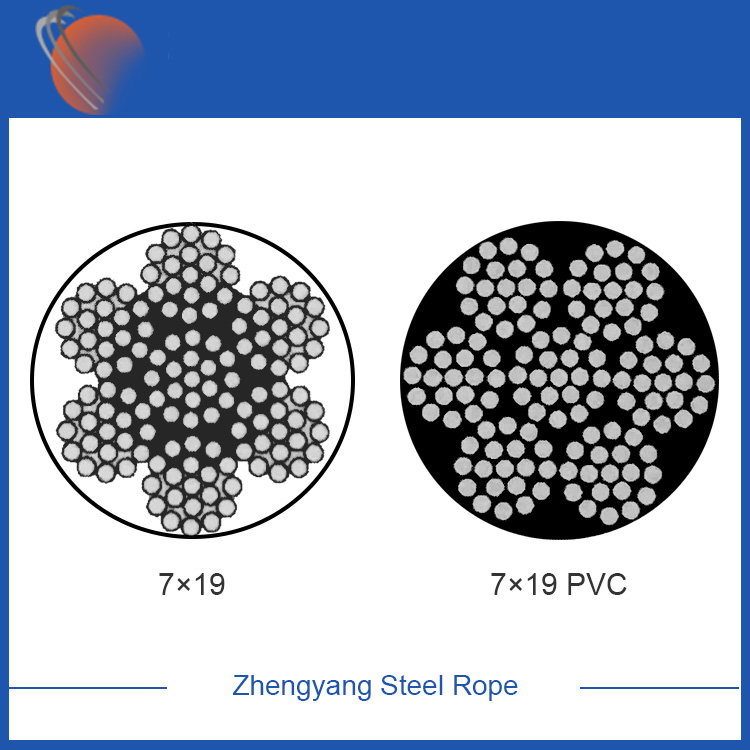

4. Construction:

- Wire ropes come in various constructions, each designed for specific applications. Common constructions include 6x19 (six strands with 19 wires per strand), 6x37, and 8x19.

5. Diameter:

- Steel wire ropes are available in a range of diameters to suit different applications. Larger diameter ropes generally have higher load-carrying capacities.

6. Lay:

- The lay of a wire rope refers to the direction of the twist in the wires and strands. Common lay types include regular lay and lang lay. The choice of lay depends on factors such as application and load direction.

7. Strength and Load Capacity:

- Steel wire ropes are known for their high tensile strength, making them suitable for lifting, hoisting, and towing applications. Load capacity is influenced by factors such as diameter, construction, and material.

8. Flexibility:

- The design and construction of steel wire ropes provide flexibility, allowing them to bend and conform to the shapes required in various applications.

9. Corrosion Resistance:

- While steel provides strength, it is susceptible to corrosion. Galvanized or stainless steel wire ropes are used in applications where resistance to corrosion is essential.

10. Applications:

- Steel wire ropes are widely used in industries such as construction, mining, maritime, transportation, oil and gas, and infrastructure. They are employed for purposes such as lifting, hoisting, rigging, towing, and suspension.

11. Inspection and Maintenance:

- Regular inspection and maintenance are crucial for ensuring the safety and performance of steel wire ropes. Factors such as wear, broken wires, and corrosion should be monitored.

12. Regulations and Standards:

- Depending on the application, steel wire ropes may need to comply with industry-specific regulations and standards to ensure safety and reliability.

Steel wire ropes are versatile and find applications in diverse industries due to their strength, durability, and flexibility. The specific type of steel wire rope selected depends on the intended use, environmental conditions, and load requirements. Regular inspection and proper maintenance are essential to ensure the continued reliability and safety of wire ropes in various applications.