Bottom Rollers: The Unsung Heroes of Material Handling and Conveyor Systems

2024-08-10

In the world of industrial machinery and material handling, the bottom roller might not be the most glamorous component, but its role is undeniably crucial. These versatile parts are integral to the smooth operation of conveyor systems and various other applications, ensuring efficient movement and handling of materials. This blog delves into the functionality, benefits, and applications of bottom rollers, shedding light on why they are essential in numerous industrial settings.

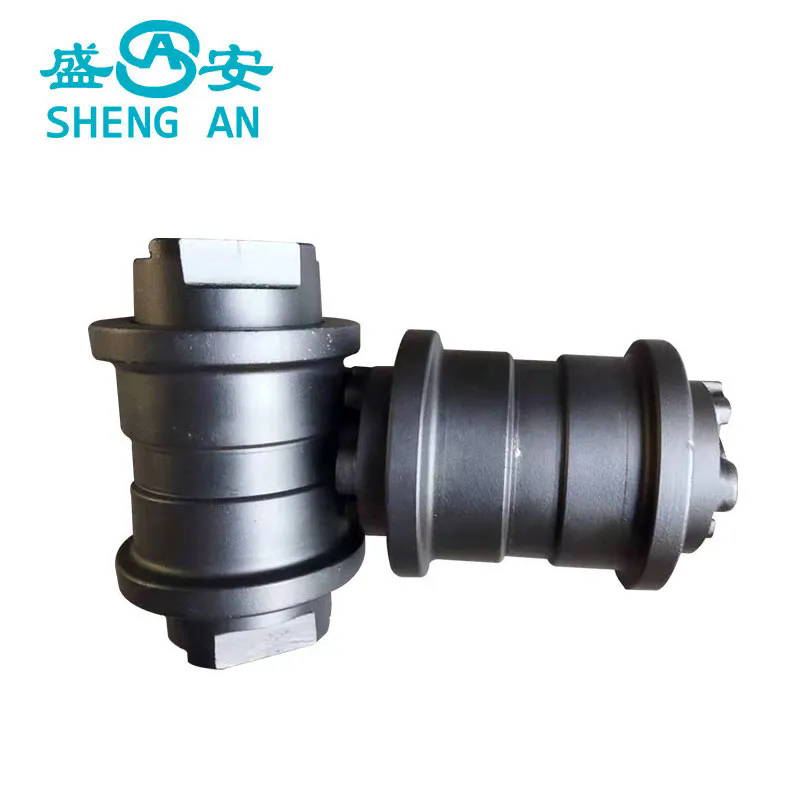

What Is a Bottom Roller?

A bottom roller, also known as a support roller or return roller, is a cylindrical component used in conveyor systems and other material handling equipment. Positioned along the bottom of the conveyor belt, it supports and guides the belt as it moves, ensuring smooth and efficient operation. The roller typically consists of a metal or plastic tube with bearings that allow it to rotate freely.

Key Features of Bottom Rollers

1. Durable Construction

- Material Quality: Bottom rollers are often made from robust materials such as steel, stainless steel, or high-density plastic. This ensures they can withstand the weight and stress of heavy loads and challenging operational environments.

- Corrosion Resistance: Many bottom rollers are coated or treated to resist corrosion, extending their lifespan in harsh conditions.

2. Smooth Rotation

- Bearings: Equipped with high-quality bearings, bottom rollers enable smooth rotation, reducing friction and wear on the conveyor belt.

- Low Noise: Well-designed rollers minimize noise during operation, contributing to a quieter work environment.

3. Adjustable and Modular Designs

- Adjustable Features: Some bottom rollers come with adjustable features to accommodate varying belt tensions and alignment requirements.

- Modular Construction: Modular designs allow for easy replacement and maintenance, reducing downtime and operational disruptions.

Benefits of Bottom Rollers

1. Enhanced Conveyor Performance

- Belt Support: Bottom rollers provide essential support to the conveyor belt, preventing sagging and ensuring even load distribution.

- Reduced Friction: By facilitating smooth rotation, bottom rollers reduce friction between the belt and the conveyor structure, leading to more efficient operation.

2. Improved Material Handling

- Consistent Movement: Bottom rollers ensure the consistent movement of materials along the conveyor belt, improving overall handling efficiency.

- Load Distribution: Even load distribution prevents belt damage and extends the life of both the conveyor belt and the rollers.

3. Durability and Longevity

- Extended Service Life: High-quality bottom rollers are designed for durability, withstanding heavy loads and harsh operational conditions over extended periods.

- Reduced Maintenance: Reliable rollers require less frequent maintenance and replacement, lowering operational costs and minimizing downtime.

4. Enhanced Safety

- Stable Operation: By providing stable support for the conveyor belt, bottom rollers contribute to safer operation, reducing the risk of accidents caused by belt misalignment or failure.

- Improved Reliability: A well-maintained roller system enhances the overall reliability of the conveyor, ensuring consistent and safe material handling.

Applications of Bottom Rollers

1. Manufacturing and Production

- Assembly Lines: Bottom rollers are used in assembly lines to support and guide conveyor belts, facilitating efficient movement of parts and products through various stages of production.

- Packaging: In packaging facilities, bottom rollers help transport products to packaging stations, improving workflow and efficiency.

2. Logistics and Warehousing

- Sorting Systems: In logistics and warehousing, bottom rollers are integral to sorting systems, allowing for smooth and accurate movement of packages and goods.

- Distribution Centers: They are used in distribution centers to handle large volumes of products, ensuring timely and efficient processing.

3. Mining and Quarrying

- Material Handling: In mining and quarrying operations, bottom rollers support conveyor belts that transport mined materials, contributing to effective material handling and processing.

- Heavy-Duty Applications: Designed for heavy-duty use, bottom rollers in these industries are built to withstand the harsh conditions and heavy loads typical of mining operations.

4. Food Processing

- Hygienic Transport: In food processing facilities, bottom rollers are used in conveyor systems that handle food products, requiring materials that are easy to clean and maintain.

- Temperature Resistance: Some rollers are designed to withstand extreme temperatures, making them suitable for various food processing applications.

Choosing the Right Bottom Roller

1. Consider Load Requirements

- Weight Capacity: Select bottom rollers with the appropriate weight capacity to handle the loads they will support. Overloading can lead to premature wear and failure.

- Belt Width: Ensure the roller is compatible with the width of the conveyor belt to provide proper support and alignment.

2. Evaluate Environmental Conditions

- Material Compatibility: Choose rollers made from materials suited to the operational environment, such as corrosion-resistant materials for wet or corrosive conditions.

- Temperature Tolerance: Consider the temperature range the rollers will be exposed to and select rollers that can withstand these conditions.

3. Maintenance and Replacement

- Ease of Maintenance: Opt for rollers that are easy to maintain and replace, minimizing downtime and maintenance efforts.

- Quality Assurance: Choose high-quality rollers from reputable manufacturers to ensure durability and reliable performance.

Conclusion

Bottom rollers are essential components in the smooth and efficient operation of conveyor systems and various material handling applications. Their role in supporting and guiding conveyor belts cannot be overstated, as they contribute to enhanced performance, safety, and durability.

By understanding the features, benefits, and applications of bottom rollers, you can make informed decisions that improve the efficiency and reliability of your material handling systems. Whether in manufacturing, logistics, mining, or food processing, bottom rollers are the unsung heroes that keep your operations running smoothly.