Common auto parts that may be made from aluminum coils

2024-03-16

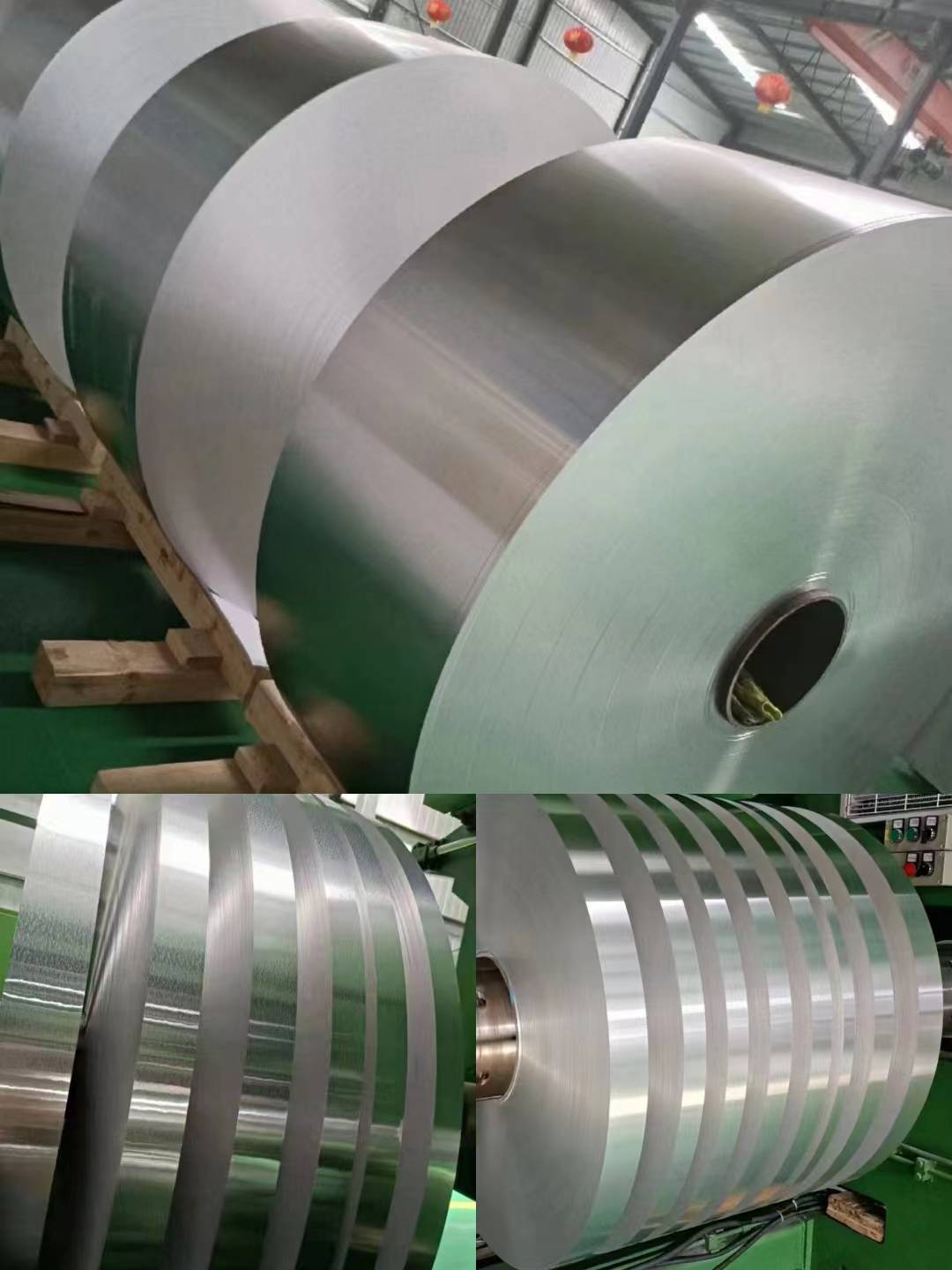

Aluminum coils are versatile materials used in various industries, including automotive manufacturing. Here are some common auto parts that may be made from aluminum coils:

1. Heat Exchangers: Aluminum coils are often used to manufacture heat exchangers for automotive cooling systems, including radiators, condensers, and evaporators. The lightweight and excellent thermal conductivity of aluminum make it ideal for dissipating heat efficiently.

2. Body Panels: Some automotive manufacturers use aluminum coils to produce lightweight body panels, such as hoods, doors, fenders, and trunk lids. Aluminum's high strength-to-weight ratio helps reduce vehicle weight, improving fuel efficiency and performance.

3. Engine Components: Certain engine components, such as cylinder heads, intake manifolds, and engine blocks, may incorporate aluminum coils in their construction. Aluminum's durability and heat resistance make it suitable for withstanding the high temperatures and stresses within an engine.

4. Suspension Components: Aluminum coils can be formed into various suspension components, including control arms, knuckles, and sway bars. These lightweight parts help reduce unsprung weight, improving handling and ride quality.

5. Wheel Rims: Aluminum coils are commonly used to manufacture lightweight alloy wheels for automotive applications. Aluminum wheels offer advantages such as improved performance, better fuel efficiency, and enhanced aesthetics compared to traditional steel wheels.

6. Structural Components: Aluminum coils may be used to produce structural components within the vehicle's chassis and frame. These components contribute to the overall strength, rigidity, and safety of the vehicle while minimizing weight.

7. Interior Trim: Aluminum coils can be formed into interior trim components, such as dashboard panels, door trim, and center console accents. Aluminum's versatility allows for the creation of stylish and durable interior elements.

8. Exterior Trim: Exterior trim elements, such as window frames, roof rails, and grille surrounds, may also be fabricated from aluminum coils. Aluminum trim provides a sleek and modern appearance while offering corrosion resistance and durability.

9. Battery Enclosures: With the growing popularity of electric vehicles (EVs), aluminum coils are increasingly used in the fabrication of battery enclosures. These enclosures protect the vehicle's battery pack while maintaining structural integrity and thermal management.

10. Fuel Tanks: In some cases, aluminum coils are used to manufacture lightweight fuel tanks for automotive applications. Aluminum tanks offer advantages such as corrosion resistance, durability, and reduced weight compared to traditional steel tanks.

These are just a few examples of auto parts that may be produced using aluminum coils. The versatility, lightweight nature, and corrosion resistance of aluminum make it a popular choice for various automotive components, contributing to improved performance, efficiency, and durability in modern vehicles.