Considerations regarding GFR-PEEK sheets

2024-01-06

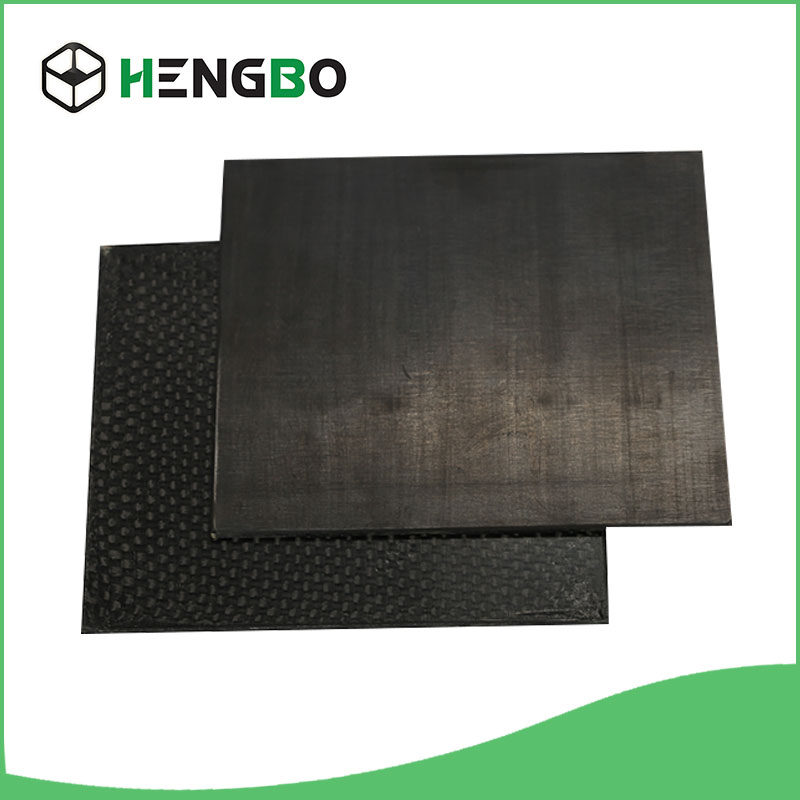

CFRTP stands for Continuous Fiber Reinforced Thermoplastic, and CFRTP sheets are composite materials made by reinforcing a thermoplastic polymer matrix with continuous fibers, typically carbon fibers. These sheets combine the strength and stiffness of the continuous fibers with the versatility of thermoplastics, resulting in a high-performance material. Here are key features and considerations regarding CFRTP sheets:

1. Continuous Fiber Reinforcement:

- CFRTP sheets are characterized by the continuous reinforcement of fibers, commonly carbon fibers, within a thermoplastic matrix. The continuous fibers provide strength, stiffness, and enhanced mechanical properties.

2. Thermoplastic Matrix:

- The matrix material is a thermoplastic polymer, which means it can be melted and reformed multiple times without significant degradation. Common thermoplastics used in CFRTP sheets include polypropylene (PP), polyethylene (PE), polyetheretherketone (PEEK), and others.

3. High Strength-to-Weight Ratio:

- The continuous fiber reinforcement imparts a high strength-to-weight ratio to CFRTP sheets. This makes them suitable for applications where lightweight, yet strong, materials are required.

4. Mechanical Properties:

- CFRTP sheets exhibit excellent mechanical properties, including high tensile strength, stiffness, and impact resistance. The specific properties depend on factors such as the type of fiber, fiber orientation, and the choice of thermoplastic matrix.

5. Dimensional Stability:

- CFRTP sheets typically offer good dimensional stability due to the reinforcing fibers, making them suitable for applications where precise dimensions are critical.

6. Customizable Fiber Orientation:

- Manufacturers can customize the orientation of the continuous fibers within the matrix during the production process. This allows for tailoring the material to meet specific performance requirements for different applications.

7. Processing Methods:

- CFRTP sheets can be processed using various manufacturing methods, including compression molding, injection molding, and thermoforming. This versatility in processing methods makes them adaptable to different production techniques.

8. Applications:

- CFRTP sheets find applications in industries such as automotive, aerospace, sporting goods, and industrial manufacturing. They are used for components requiring a balance of strength, stiffness, and light weight.

9. Cost Considerations:

- While CFRTP sheets offer high performance, the cost can be a factor compared to traditional materials. However, their benefits in terms of weight reduction and performance often justify their use in specific applications.

10. Recyclability:

- The recyclability of CFRTP sheets depends on the specific thermoplastic matrix used. Some thermoplastics allow for easy recycling, while others may require more specialized processes.

11. Environmental Impact:

- CFRTP sheets can contribute to lightweighting in transportation applications, which can result in reduced fuel consumption and lower emissions. However, the environmental impact also depends on factors such as material selection, manufacturing processes, and end-of-life considerations.

When considering CFRTP sheets for a particular application, it's essential to evaluate the specific requirements and performance characteristics needed. Collaboration with material suppliers and manufacturers can help in selecting the most suitable CFRTP material for the intended use.