Considerations Regarding Marine communication cables

2024-04-23

Marine communication cables are specialized cables designed for use in maritime and offshore communication systems. These cables are engineered to withstand the harsh conditions of marine environments, including exposure to water, salt, extreme temperatures, and mechanical stress. Here are some key features and considerations regarding marine communication cables:

1. Water Resistance: Marine communication cables are designed to resist water ingress and moisture penetration, ensuring reliable performance even when submerged or exposed to high humidity levels. They are typically constructed with water-resistant materials and protective layers to prevent damage to internal components.

2. Saltwater Resistance: In addition to water resistance, marine communication cables are engineered to withstand exposure to saltwater, which can be highly corrosive. Specialized materials and coatings are used to protect the cables from corrosion and degradation caused by saltwater exposure.

3. UV Resistance: Marine communication cables may be equipped with UV-resistant outer jackets to protect against damage from prolonged exposure to sunlight. UV resistance helps maintain the integrity and performance of the cables, especially in outdoor or exposed installations.

4. Flexibility and Durability: Marine communication cables are designed to be flexible and durable, allowing for easy installation and routing in confined spaces and complex configurations. They are often constructed with stranded conductors and flexible insulation materials to withstand bending and flexing without damage.

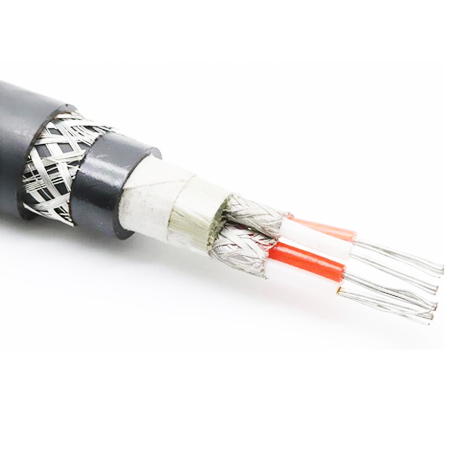

5. Electromagnetic Interference (EMI) Shielding: To ensure reliable signal transmission in marine environments, communication cables may be equipped with shielding layers to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). Shielding helps maintain signal integrity and minimize disruptions from external electromagnetic sources.

6. Corrosion Resistance: Marine communication cables are often constructed with materials that are resistant to corrosion, such as copper conductors with corrosion-resistant plating or alloys. This helps prevent degradation of electrical conductivity and ensures long-term reliability in corrosive marine environments.

7. Fire Resistance: Some marine communication cables are designed to meet specific fire safety standards and regulations, such as those outlined by organizations like the International Maritime Organization (IMO). Fire-resistant cables feature flame-retardant materials and construction to minimize the spread of fire and smoke in the event of a fire onboard a vessel.

8. Compliance with Standards: Marine communication cables must comply with relevant industry standards and regulations, such as those set by organizations like the International Electrotechnical Commission (IEC), American Bureau of Shipping (ABS), and Lloyd's Register (LR). Compliance ensures that the cables meet safety, performance, and reliability requirements for maritime and offshore applications.

When selecting marine communication cables, it's essential to consider factors such as water resistance, saltwater resistance, UV resistance, flexibility, durability, EMI shielding, corrosion resistance, fire resistance, and compliance with industry standards. Additionally, consulting with marine engineering professionals and adhering to specific requirements for marine communication systems will help ensure the selection of suitable cables for the intended application.