Features and applications of cement resistors

2023-11-08

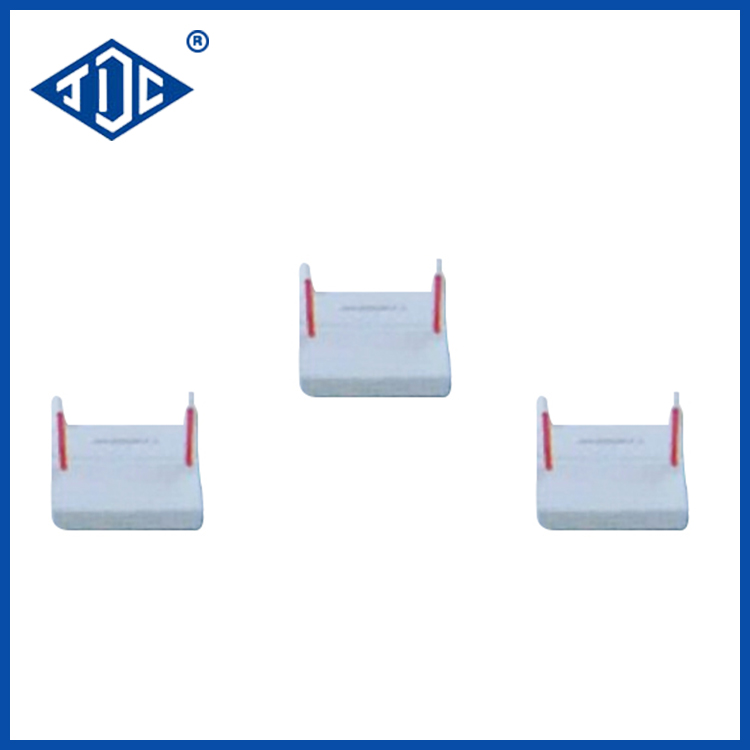

A cement resistor, also known as a power resistor or wirewound resistor with a cement core, is an electronic component designed to limit or control the flow of electric current in a circuit by introducing electrical resistance. Cement resistors are known for their high power-handling capabilities and are typically used in applications where dissipating significant amounts of heat is essential. Here are some key features and applications of cement resistors:

Key Features:

1. Cement Core: The distinctive feature of cement resistors is their cylindrical ceramic core, often coated with a layer of cement. The resistive element is usually a wire wound around this core.

2. High Power Handling: Cement resistors are designed to handle high power levels without overheating, making them suitable for applications where power dissipation is a concern.

3. Low Inductance: These resistors typically have low inductance, making them suitable for high-frequency applications and minimizing unwanted electrical effects.

4. Resistance Value: Cement resistors are available in various fixed resistance values, typically marked using color bands or numeric codes. The resistance value is predetermined during manufacturing and cannot be adjusted by the user.

5. Tolerance: Like other resistors, cement resistors have a specified tolerance that indicates the range within which the actual resistance may vary from the specified value. Common tolerances for cement resistors are ±5% and ±1%.

6. Temperature Coefficient: Cement resistors may have a low temperature coefficient, meaning their resistance value changes only slightly with temperature variations.

7. Stability: They offer good long-term stability and reliability, with minimal drift in their resistance value over time.

Applications:

1. Load Resistors: Cement resistors are commonly used as load resistors in various electrical and electronic devices, dissipating excess power generated during operation.

2. Power Electronics: They are employed in power electronics applications, such as power supplies, motor drives, and inverter circuits, where they help manage high current and voltage levels.

3. Braking and Snubbing: In electric vehicles and industrial equipment, cement resistors can serve as braking or snubbing resistors to dissipate excess energy generated during braking or deceleration.

4. Heating Elements: Cement resistors are used as heating elements in devices like industrial ovens, heaters, and electric stoves.

5. Industrial Equipment: They are used in a variety of industrial equipment, including welding machines, high-power amplifiers, and robotics.

6. Renewable Energy: Cement resistors can be used in renewable energy systems, such as wind turbines and solar inverters, to control and manage power levels.

7. Automotive Electronics: These resistors can be found in automotive applications, including electronic control units (ECUs), ignition systems, and power management circuits.

8. Test and Measurement Equipment: Cement resistors are used in test and measurement devices where precise resistance values and power handling are crucial.

Cement resistors are well-suited for applications that require efficient heat dissipation and power handling capabilities, especially in high-power electronic and industrial equipment. Their reliability and long service life make them a suitable choice for demanding and mission-critical applications where power dissipation is a primary consideration.