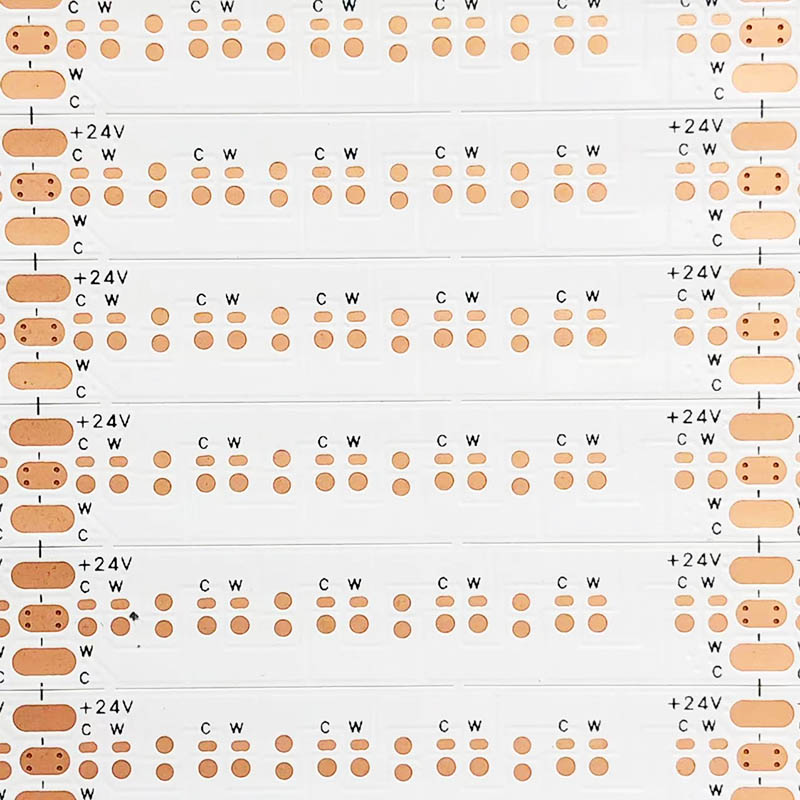

Flexible Printed Circuit Board (FPC): Lightweight, Bendable, and High-Density Interconnect Solutions

2025-07-14

A Flexible Printed Circuit Board (FPC) is a type of electronic circuit board that is designed to be flexible, bendable, and sometimes foldable. It consists of conductive traces etched onto a flexible polymer substrate, allowing for compact and adaptable electronic assemblies.

What is a Flexible Printed Circuit Board?

Unlike traditional rigid PCBs, flexible PCBs use flexible materials such as polyimide or polyester films as substrates. This enables the circuit to bend, fold, or twist without damaging the conductive pathways, making them ideal for complex or compact electronic designs.

Key Features of Flexible Printed Circuit Boards

Flexibility: Can be bent or shaped to fit tight or irregular spaces.

Lightweight and Thin: Reduces overall device weight and thickness.

High-Density Interconnect: Supports fine circuit lines for complex electronic functions.

Durability: Resistant to vibration and mechanical stress.

Thermal Stability: Polyimide substrates offer high heat resistance.

Reliable Electrical Performance: Maintains conductivity despite repeated flexing.

Types of Flexible Printed Circuit Boards

Single-Sided FPC

One layer of conductive material on a flexible substrate.

Used for simple circuits.

Double-Sided FPC

Two conductive layers separated by a flexible insulating layer.

Enables more complex circuit designs.

Multi-Layer FPC

Multiple layers laminated together for high-density and complex circuitry.

Used in advanced electronics.

Rigid-Flex PCB

Combines rigid and flexible substrates in one board.

Provides structural support where needed while maintaining flexibility.

Applications of Flexible Printed Circuit Boards

Consumer electronics (smartphones, tablets, wearables).

Medical devices (implantable sensors, diagnostic equipment).

Automotive electronics (dashboard controls, sensors).

Aerospace and defense (compact and lightweight electronic systems).

Industrial equipment (flexible sensors, control systems).

Benefits of Using Flexible PCBs

Design Flexibility: Enables innovative, compact product designs.

Reduced Weight and Volume: Ideal for portable and wearable devices.

Improved Reliability: Minimizes wiring and connector failures.

Cost Savings: Can reduce assembly time and complexity.

Enhanced Durability: Tolerant to vibration and mechanical stress.

Manufacturing Considerations

Requires precise etching and lamination processes.

Design must account for bending radius and stress points.

Protective coatings may be applied for environmental resistance.

Testing for electrical continuity and mechanical durability is critical.

Conclusion

Flexible Printed Circuit Boards (FPCs) are essential components in modern electronics, offering unmatched design flexibility, space savings, and reliability. Their ability to conform to complex shapes has revolutionized electronic device design across industries.