Keyboard Precision Stampings: The Backbone of Modern Keyboards

2025-04-28

In the world of technology, it’s easy to focus on flashy features and cutting-edge designs, but there are countless small components that make these devices work seamlessly. One such crucial component is keyboard precision stampings. These tiny, often overlooked parts are essential for ensuring that your keyboard responds with accuracy and durability.

But what exactly are keyboard precision stampings, and why are they so important? Let’s take a closer look at these hidden heroes of your everyday keyboard.

What are Keyboard Precision Stampings?

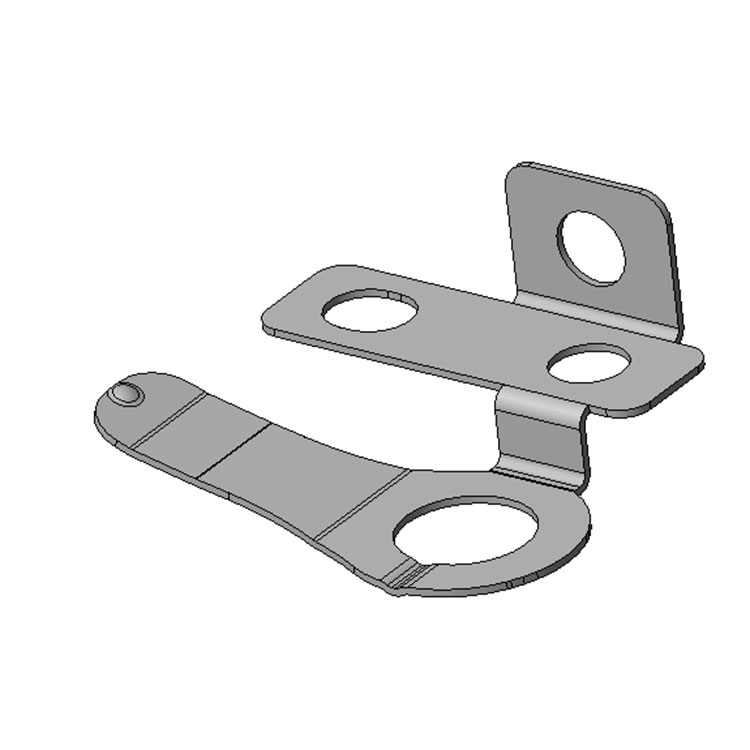

Keyboard precision stampings are small metal parts created through a stamping process, which involves pressing or stamping metal sheets into precise shapes using high pressure and specialized molds. In the case of keyboards, these stamped components are primarily used to create the switch mechanisms that allow the keys to respond when pressed.

These stampings are designed to be highly accurate and durable, ensuring that the keyboard operates smoothly over time. The process allows for mass production of these components with high precision, which is crucial for maintaining consistent quality across keyboards.

How Are Keyboard Precision Stampings Made?

The creation of keyboard precision stampings begins with selecting the right metal materials, which are typically stainless steel or other durable alloys. These materials are chosen for their ability to withstand frequent use and resist wear and tear.

Once the metal sheets are prepared, they are fed into a die (a mold), where they are subjected to high pressure. This pressure shapes the metal into the desired component, whether it’s a spring, contact, or switch housing. The stamping process is extremely accurate, meaning that the components are made to exact specifications, ensuring that every key on a keyboard functions properly.

After the stamping is done, the components undergo various processes like deburging (removing any sharp edges) and surface treatment (such as coating or plating) to further enhance their durability and performance.

Why Are Keyboard Precision Stampings Important?

1. Accuracy and Responsiveness

One of the primary roles of keyboard precision stampings is to ensure that the keyboard responds accurately to each keystroke. These parts form the switch mechanisms, which control how the keys register when pressed. Without precision in these components, your keyboard could experience delayed or inaccurate key presses, which would make typing frustrating and inefficient.

2. Durability

A high-quality keyboard stamping is built to last, with many keyboards designed to handle millions of keystrokes before showing any signs of wear. This is particularly important for mechanical keyboards, which rely heavily on these precision components to function smoothly over time. Precision stampings ensure that the keyboard’s switches maintain their performance long after the first use.

3. Cost-Effective Mass Production

Precision stamping allows for mass production of components with high consistency and low cost. Since the process is highly automated, manufacturers can produce thousands or even millions of keyboard switches without sacrificing quality. This ensures that consumers receive affordable, high-quality keyboards that perform reliably.

4. Customization and Versatility

The precision and flexibility of the stamping process allow manufacturers to design a wide range of keyboard components, including key switches, actuators, contact points, and springs, each tailored to specific needs. This is why keyboards come in so many different styles—whether you’re looking for mechanical switches with a tactile click or low-profile keys for a sleek design.

Applications of Keyboard Precision Stampings

While computers and laptops are the most common devices that use keyboard precision stampings, they’re also found in a wide range of other electronics and machinery. These include:

- Point of sale (POS) terminals

- Medical devices with keypads

- Industrial control panels

- Consumer electronics, such as calculators or handheld devices

In all of these applications, precision stampings ensure that the buttons and switches work reliably, contributing to the overall functionality and longevity of the device.

The Future of Keyboard Precision Stampings

As technology advances, the demand for keyboards and keypads with even more sophisticated features is on the rise. Smartphones, tablets, and other devices are incorporating capacitive touch screens, while mechanical keyboards continue to be favored by gamers and professionals for their tactile feedback.

However, the precision stamping process will remain a critical part of this evolution. As keyboard designs continue to evolve, manufacturers are working to make the process more efficient, sustainable, and versatile. This means creating components that are lighter, more durable, and more precise than ever before—ensuring that our keyboards continue to provide the perfect balance of form and function.

Conclusion

Keyboard precision stampings may be small, but they’re absolutely essential to the performance and durability of keyboards. They provide the accuracy, responsiveness, and durability that make your keyboard feel just right every time you press a key. Whether you’re typing up a report, gaming, or sending a quick message, those little stamped components ensure that your keyboard works the way it should—every single time.

So, next time you’re typing away, take a moment to appreciate the precision stampings that make it all possible. These humble components are the unsung heroes of the modern keyboard, quietly ensuring that your device performs at its best.