Unveiling the Power of Alumina Ceramic: A Guide to Its Applications and Benefits

2024-08-19

In the realm of advanced materials, alumina ceramic stands out for its remarkable properties and versatility. Widely used across various industries, alumina ceramics are known for their durability, high performance, and resistance to extreme conditions. In this blog, we will explore what alumina ceramic is, its key properties, benefits, applications, and the future trends shaping this essential material.

What is Alumina Ceramic?

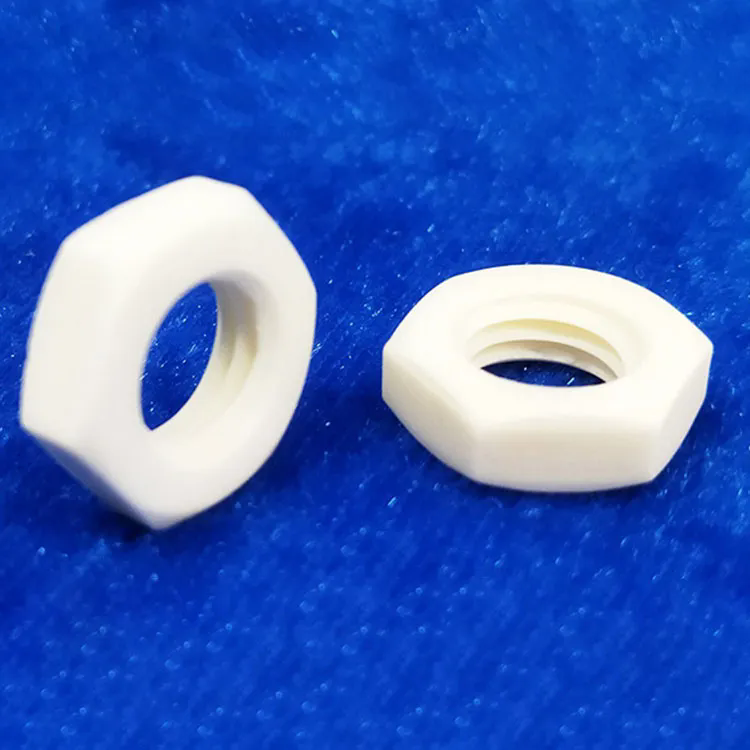

Alumina ceramic, also known as aluminum oxide, is a type of ceramic material composed primarily of aluminum oxide. It is produced through the sintering of alumina powder at high temperatures, which results in a dense, hard material. Alumina ceramics are valued for their exceptional hardness, wear resistance, and electrical insulating properties, making them suitable for a wide range of applications.

Key Properties of Alumina Ceramic

1. High Hardness: Alumina ceramic is known for its exceptional hardness, making it one of the hardest ceramic materials available. This property is crucial for applications requiring abrasion resistance and durability.

2. Wear Resistance: Due to its hardness and strength, alumina ceramic exhibits excellent wear resistance, which is beneficial for components subjected to friction and erosion.

3. High Thermal Stability: Alumina ceramics can withstand high temperatures without degrading, making them suitable for use in high-temperature environments.

4. Electrical Insulation: Alumina ceramics are excellent electrical insulators, with high dielectric strength and low electrical conductivity. This makes them ideal for electronic and electrical applications.

5. Chemical Resistance: Alumina ceramic is resistant to many chemicals, including acids and bases, which extends its usability in harsh chemical environments.

6. Low Thermal Conductivity: The low thermal conductivity of alumina ceramics helps in insulating applications, preventing heat transfer and reducing energy loss.

Benefits of Alumina Ceramic

1. Durability and Longevity: Alumina ceramics are highly durable and have a long service life, which reduces the need for frequent replacements and maintenance.

2. Enhanced Performance: The hardness and wear resistance of alumina ceramics contribute to improved performance in various applications, from industrial machinery to electronic components.

3. Cost-Effectiveness: Although alumina ceramics can be more expensive upfront compared to some materials, their durability and performance often lead to long-term cost savings due to reduced maintenance and replacement needs.

4. Versatility: Alumina ceramics can be engineered to meet specific requirements, such as varying degrees of hardness, thermal resistance, and electrical insulation, making them versatile for a wide range of applications.

5. Environmental Resistance: The chemical and thermal resistance of alumina ceramics ensures that they can perform reliably in harsh environmental conditions, including extreme temperatures and corrosive environments.

Applications of Alumina Ceramic

1. Industrial Applications: Alumina ceramics are widely used in industrial applications such as wear-resistant liners, grinding media, and cutting tools. Their high hardness and wear resistance make them ideal for these demanding environments.

2. Electronics and Electrical: In the electronics industry, alumina ceramics are used as substrates and insulators in electronic components such as capacitors, resistors, and semiconductors. Their electrical insulating properties ensure reliable performance in electronic devices.

3. Medical Devices: Alumina ceramics are utilized in medical applications, including prosthetics, dental implants, and surgical instruments. Their biocompatibility, strength, and resistance to wear make them suitable for these critical applications.

4. Aerospace and Defense: In aerospace and defense industries, alumina ceramics are used in armor systems, thermal protection systems, and engine components. Their high hardness and thermal stability provide protection and performance under extreme conditions.

5. Automotive Industry: Alumina ceramics are employed in automotive components such as spark plugs, sensors, and catalytic converters. Their durability and thermal properties enhance the performance and reliability of these parts.

6. Energy Sector: Alumina ceramics are used in energy applications, including fuel cells and high-temperature reactors. Their thermal and chemical resistance ensures efficient and stable operation in these demanding environments.

Future Trends and Innovations

The field of alumina ceramics continues to evolve, with several exciting trends and innovations on the horizon:

1. Advanced Processing Techniques: New processing techniques, such as additive manufacturing (3D printing), are enabling the production of complex alumina ceramic components with enhanced properties and precision.

2. Enhanced Materials: Research into composite materials and advanced formulations is leading to the development of alumina ceramics with improved performance characteristics, including increased toughness and reduced brittleness.

3. Sustainable Manufacturing: Efforts are being made to improve the sustainability of alumina ceramic production by reducing energy consumption, minimizing waste, and using environmentally friendly raw materials.

4. Integration with Smart Technologies: The integration of smart technologies and sensors into alumina ceramic components is enhancing their functionality and enabling real-time monitoring and control in various applications.

5. Expanded Applications: Ongoing research is exploring new applications for alumina ceramics in emerging fields such as renewable energy, nanotechnology, and advanced manufacturing, broadening their scope and impact.

Conclusion

Alumina ceramic stands as a testament to the power of advanced materials in transforming industries and enhancing performance across a wide range of applications. Its exceptional properties, including hardness, wear resistance, and electrical insulation, make it a valuable material in both traditional and cutting-edge technologies. By understanding the benefits, applications, and future trends of alumina ceramics, you can appreciate their role in driving innovation and supporting the advancement of various fields. As research and development continue to push the boundaries of ceramic technology, alumina ceramics will undoubtedly play a crucial role in shaping the future of materials science and engineering.